The Hyperloop is the future of transportation, bringing the benefits of air travel to the ground. A hyperloop is a train that can travel at the speed of sound within an evacuated tube. In theory people could go from LA to San Fransisco in 35 minutes. SpaceX began a competition in 2015 for university teams to design build and test a scaled version of the hyperloop. Around this time I was looking to start a project at my university (University of California, Irvine) when I heard about the hyperloop I got two of my close friends together and I signed the papers necessary to bring UCI into the competition.

At first we did not know what we were doing, to that day no one had thorougly designed a scaled model of the hyperloop. We began by doing research on current forms of transporation and seeing how we could apply them to the current challenge, some things we looked into were trains, land speed record cars, even jets! The apperent question became what form of low friction levitation were we going to implement. Some rough designes called for air levitation, others magnetic. My two collueges and I were able to amas a group of 10 undergraduate and graduate students to begin the inital design work for the hyperloop.

During the design phase I overlooked how the system would go together and would collaborate on designs mechanics for certain subsystems. Making sure every subsytem worked well together and fit in the final package was my biggest concern. I emphasized with my team to design with known components or comercai off the shelf, in order to stream line the process and make building the hyperloop a reality in the time we had available.

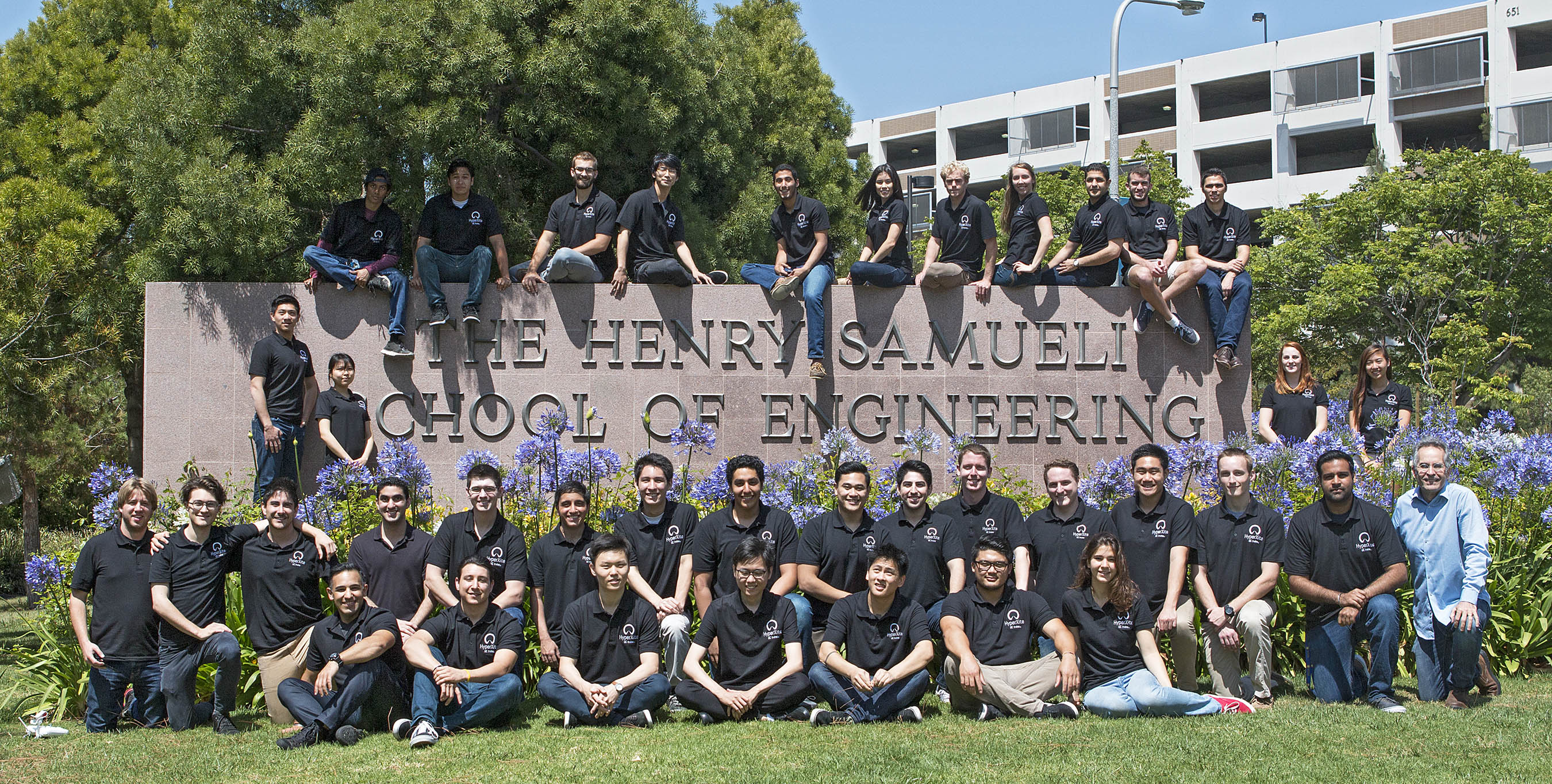

We ended up winning 5th place for design excelence out of 128 teams around the world in the hyperloop design weekend! After this stage of the competition my team grew significantly to fifty two students! We changed our focus from pure design to a manufacturing mindset. This included connecting with sponsors, percuring parts, and improving and finalizing the system design. My team and I were able to raise $400,000 in investments to the pod which included training for multiple programs, raw materials and COTS.

A year after design weekend my team and I had a finalized pod and we competed against twenty other universities to see who not only had the best design but also the manufacturing capability to make a hyperloop prototype a reality. Below you will find four of the subsystems that I heavily colaborated on in terms of design and development on top of leading the system integration of the hyperloop.